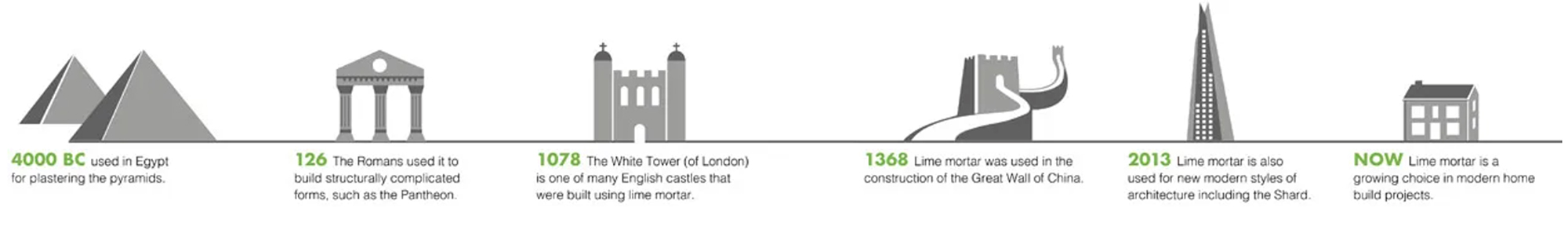

Lime is renowned for being the product of choice in conservation and heritage building projects, in maintenance, repair and extension work. This is due to its sustainable and superior properties over the more commonly used cement solutions. After all lime has been used as a binder for renders, plasters and mortars since Roman times, it was used by the Egyptians in the building of the pyramids and is a major component of the Great Wall of China.

Lime when mixed with sand creates mortar for bedding and pointing masonry, for internal plastering or external rendering and when diluted with water it creates a lime wash.

Lime has many advantages over cement:

- It's flexible – because lime never completely hardens or sets, it allows movement that is common in

historic buildings that may be built on weak or unstable foundations. When movement occurs in a wall,

the masonry is forced against the mortar. If a hard cement mortar is used, the softer stone or brick will

crack and crumble first. A lime mortar is softer and more flexible, so will ‘give’ first, thus preserving the

more valuable stone or brick.

- It's permeable – unlike a cement product which traps moisture inside a building, lime allows moisture

to evaporate, thus reducing the likelihood of damp and mould inside the building. Compatible with other materials – therefore allows numerous other materials to work together, thus

reducing the risk of materials expanding at different rates or structural cracking.

- Easily removed – lime mortar can easily and safely be removed from original materials such as brick or

stone, thus allowing them to be re-used in an un-damaged state.

- Protects other materials – when cement is used in pointing for example, because of its hardness, water

cannot escape or evaporate from the mortar, so is therefore forced out through the stone or brick face,

which over time will cause decay to the building material.

- Low carbon footprint – manufacture of lime consumes approximately 75% – 90% less energy than

cement production.

The popularity of this versatile building material is due to its many attributes, not least performance, flexibility, compatibility with other materials, enhanced aesthetics, durability and eco-credentials.

- Perfect for conservation, renovation, heritage and new build

- Lime plaster is much easier to work than cementitious product

- Mortar colour can be accurately matched

- Suitable for most brick and stonework applications and improves the

look of masonry

- Meets a wide variety of performance requirements

- Available in bags, tubs or on-site silos for large projects